What we do

PICA offers customized high-resolution electromagnetic, multi-sensor and other technology inspection solutions to a diverse client base in multiple industries with many different pipeline applications. We deliver high-resolution electromagnetic inspections that accurately measure corrosion and wall loss in metallic pipe (steel, DIP, CIP), broken wires, and corrosion and wall loss in cylinders for concrete pressure pipe (PCCP, CCP, RCP, RCCP). We specialize in pressurized and lined pipe applications for both in-service and out-of-service pipelines.

Our clients’ key challenge is aging infrastructure with unknown conditions and uncertain remaining useful life of their pipelines and, in many cases, pipes that have active leaks that have both unknown and known locations. Key challenges for our clients can be summarized as:

- Pipelines may have unknown structural or hydraulic deterioration that negatively impacts pipeline operations

- Detecting precisely where leaks and problem areas are happening

- Unexpected pipeline failures and subsequent spills

- Increasing customer or community expectations for service continuity and environmental stewardship

Our inspection and condition analysis services provide these benefits:

- Allocate the cost and schedule of rehabilitation efforts by knowing where problems are located and their severity

- Save money with targeted repairs vs. full replacement

- Reduce unplanned and emergency repairs keeping pipelines in service more consistently

- Avoid negative consequences with customers and communities

Service solutions

PICA has five service solutions that cover a spectrum of inspection services and technologies used in pipeline inspection and condition analysis.

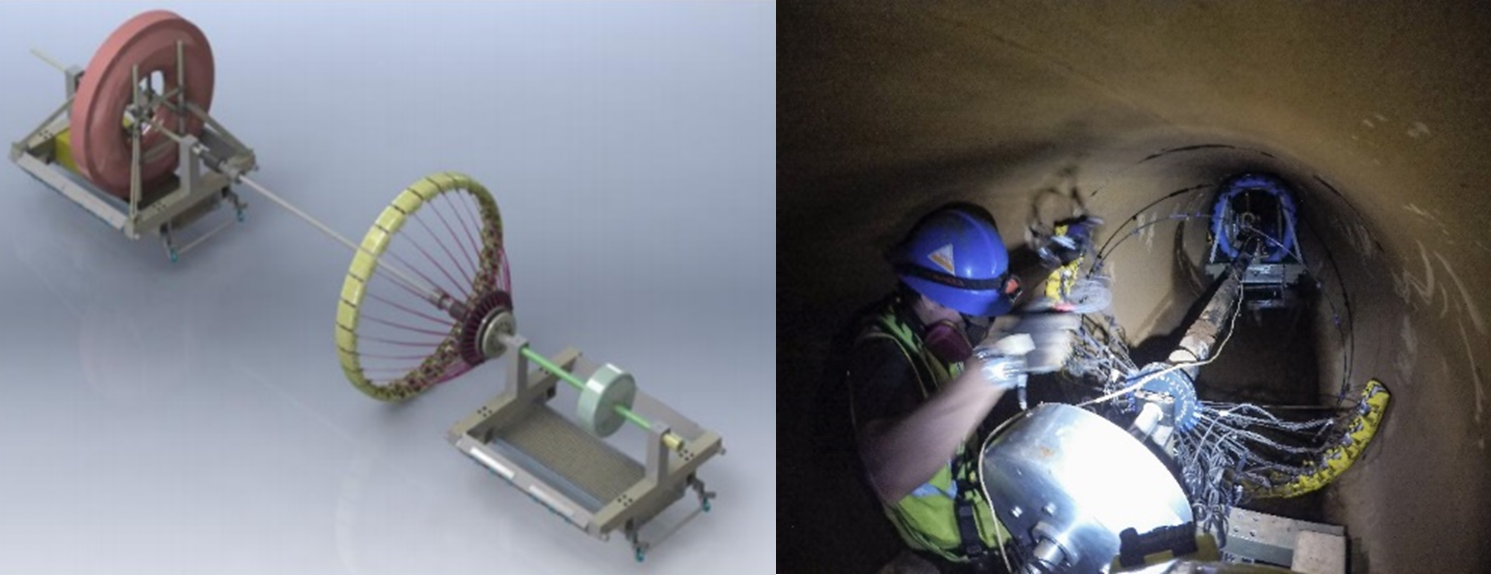

1. Pre-Screening NDT Solutions

Pipeline inspection and condition analysis service using multi-sensor and acoustic sphere inspection tools. Identifies leak and gas pocket locations with high-sensitivity acoustic and accelerometer sensors.

2. Visual NDT Solutions

Pipeline inspection and condition analysis service using CCTV, Laser and Lidar inspection tools. Delivers visual feature, profile and deformation detection in internal body and at joints that could be leading indicators of potential pipeline integrity issues for the pipeline.

3. Standard NDT Solutions

Pipeline inspection and condition analysis service using Near Field eddy current electromagnetic testing (NFT) inspection tools. Delivers identification and quantification of five or more adjacent broken wires in several dewatered concrete cylinder pipe types, such as prestressed concrete cylinder pipe (PCCP), reinforced concrete cylinder pipe (RCCP) and reinforced concrete pipe (RCP)

4. Intermediate NDT Solutions

Pipeline inspection and condition analysis service using handheld low frequency electromagnetic eddy current and ultrasonic inspection tools. Delivers localized/spot inspection for trends in wall thickness reductions, individual pits, graphitic corrosion, and erosion.

5. Advanced NDT Solutions

Pipeline inspection and condition analysis service using Remote Field eddy current electromagnetic testing (RFT or RFEC) inspection tools. Delivers high resolution, through-transmission, cross sectional pipe wall thickness measurements, detection of internal and external areas of wall loss, graphitic corrosion, cracks, or local stress concentrators in metal pipes or concrete pressure pipes.

Industries Served

PICA specializes in conducting high-resolution electromagnetic inspections of pressure pipes that are used in a variety of industries and applications. The quality of data collected from our company-designed tools is accurate, repeatable, and reliable.

WATER

WASTEWATER

INDUSTRIAL

MINING

Oil&GAS

POWER

Industries Served

PICA specializes in conducting high-resolution electromagnetic inspections of pressure pipes that are used in a variety of industries and applications. The quality of data collected from our company-designed tools is accurate, repeatable, and reliable.

WATER

WASTEWATER

INDUSTRIAL

MINING

Oil&GAS

POWER

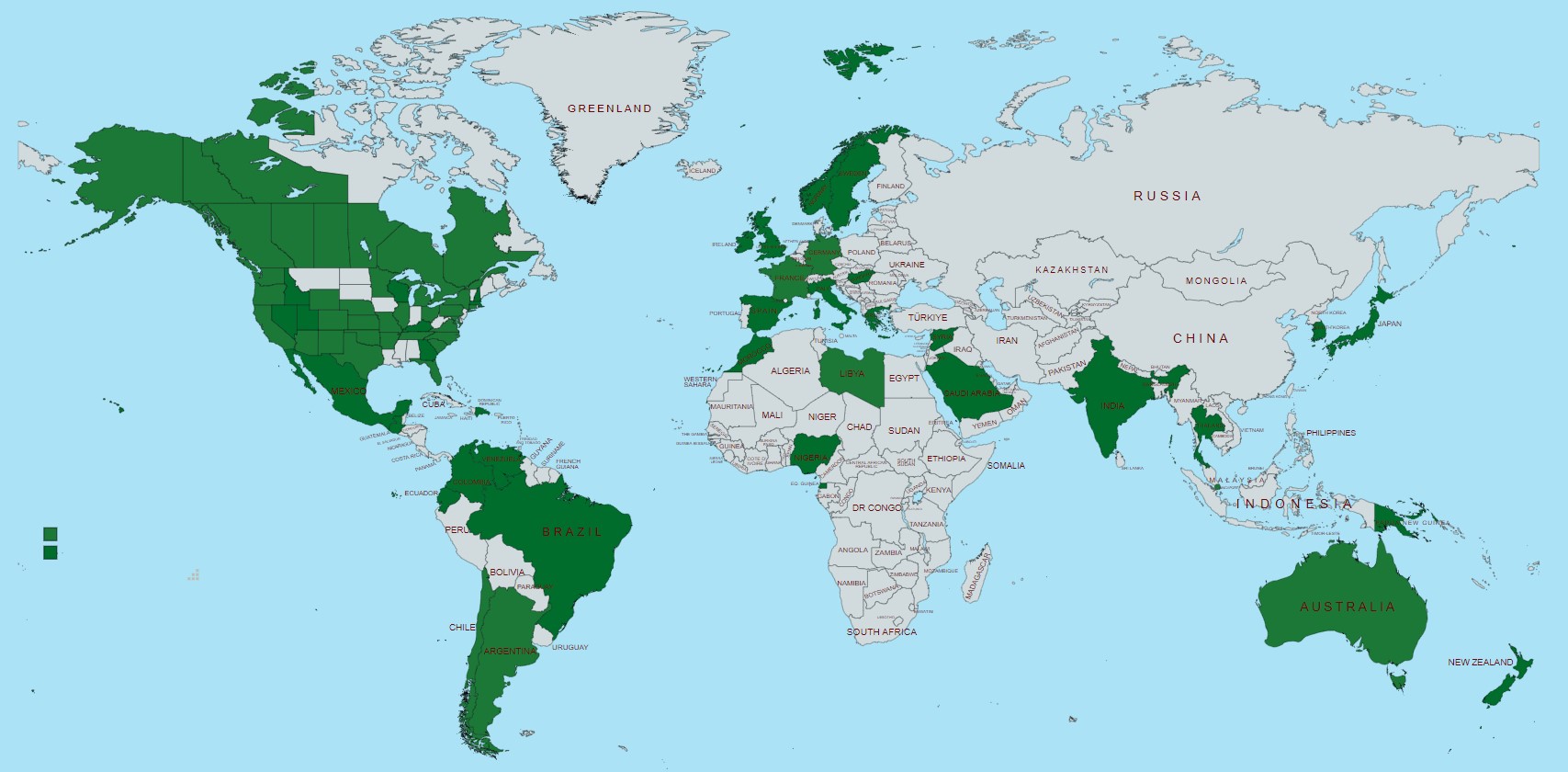

Our Worldwide Service Footprint

Explore our projects

The PICA team has the technology, expertise, and knowledge to serve each customer’s unique needs. Explore recent case studies to see how PICA works with customers to provide the right information to make good decisions about their pipelines, both in the near-term and into the future.

MICHIGAN WATER AUTHORITY SERVING POPULATION OF 3.8 MILLION

On August 13, 2022, at 4:30 a.m. a 120-inch PCCP water transmission main from Lake Huron experienced asignificant failure about one mile west of the treatment plant.

The transmission main, the largest in the regional distribution center, was constructed in 1968 of embedded cylinder PCCP. PICA was contracted by an engineering consultant to conduct an emergency mobilization and inspection of a portion of the pipeline on either side of the failure. PICA assembled and shipped a Near Field Testing (NFT) electromagnetic inspection tool to the project site within 24 hours of notification, and within two days PICA’s equipment and crew arrived on site ready to inspect the pipe.

PICA inspected a total of 1.5 miles of pipe and delivered the inspection results before PICA’s inspection crew left the site. PICA identified a number of distressed areas with large wire break counts and also flagged a discrepancy between the numbering on the lay sheets and the numbering on the interior of the pipe.

SOUTHERN CALIFORNIA WATER DISTRICT

In 2017 and 2021, PICA inspected a total of 8 miles of 36-inch diameter CMLC steel pipe and C303 bar- wrapped (concrete cylinder) pipe on a Southern California Water District’s Aqueduct #2 and Aqueduct #1 pipelines using Remote Field Testing (RFT) technology and PICA’s unique deflatable tool platform that allows insertion and extraction of tool components through 18-inch diameter access openings.

Both pipelines had experienced failures prior to PICA’s inspections. On the Aqueduct #2 steel pipeline, PICA found that 98% of the pipe was in good condition, even though PICA’s technology also found several locations of significant wall loss that was caused from external corrosion. The District made spot repairs to this pipeline and replaced certain sections. These improvements will enable the District to operate this critical raw water delivery pipeline well into the future. In 2021, under an emergency inspection, PICA identified over 350 locations of wall loss over the 2.2 miles inspected on their Aqueduct #1 bar-wrapped pipe. District personnel entered the pipe and validated PICA’s findings at several of these locations and subsequently made the necessary repairs to the pipeline that will enable them to return the pipeline to full service and extend the asset’s life substantially.

NEBRASKA CITY WITH POPULATION OF 486,051

Using the See Snake Remote Field Testing (RFT) tool, PICA inspected approximately 3,300 feet of 12-inch ductile iron pipe (DIP) to determine whether numerous breaks over a 15-year time span were indicative of the poor condition of the entire line or if the problem areas were localized to specific areas of the water main.

Chlorine tubes were used to deploy an in-line RFT inspection tool and minimize downtown for the mostly industrial customers connected to the main. The inspection identified 1,582 pitting indications, with 144 of those sizing deeper than 80% wall loss (this includes 33 indications with 0% remaining wall). Despite the high defect count, the data confirmed the engineers’ suspicion that the main was not severely corroded for its full length. Instead, the corrosion appeared to flare up in localized areas, allowing City engineers to focus their attention on those areas. Using the inspection results, the City devised an approach that combined 300 feet of main replacement with a number of surgically placed repair clamps and anodes, thereby extending the remaining useful life of the main.

MID-WEST CITY, SERVING A POPULATION OF 156,607

PICA partnered with a mid-west city in February 2023 to conduct an inspection of 4.8 miles of 54-inch embedded cylinder PCCP and 1.9 miles of lined cylinder PCCP. Near Field Testing (NFT) for wire breaks was conducted on both pipelines. Remote Field Testing (RFT) was also conducted on portions of the 54- inch pipeline with thicker cylinder and along the entire length of the 48-inch pipeline.

RFT is proving to produce a valuable data set that complements and validates the NFT wire break findings. When NFT data is analyzed on site while the pipeline is out of service, RFT can be surgically deployed in areas of interest to produce a more complete and comprehensive picture of the condition of the critical water transmission mains.

ARIZONA INDIAN COMMUNITY

In December 2022, an inspection team of PICA and Simpson Gumpertz and Heger (SGH) conducted an inspection of 8.5 miles of 78-inch and 84-inch embedded cylinder PCCP that delivers low-pressure agricultural water to an Arizona Indian Community. PICA deployed Near Field Testing (NFT) technology for wire breaks along the entire 8.5-mile length and Remote Field Testing (RFT) technology for cylinder corrosion on one mile of pipeline found in the NFT inspection to be of highest distress (i.e., highest number of wire breaks). SGH conducted visual and sounding inspection along the entire pipeline length but focused their efforts on the pipe segments found through the NFT inspection to have the highest wire break counts.

On-site analysis of NFT data enabled the PICA/SGH team to collect the best inspection data possible by a combination of inspection methods while the pipeline was out of service. Results of the inspection and the subsequent failure analysis by SGH enabled the community’s engineering consultant to plan and budget for further targeted inspections of distressed pipe sections and rehabilitation efforts that will prevent any unexpected outages of this pipeline and disruption of water delivery that is critical to the farming operations.

CALIFORNIA CITY OF 135,000 POPULATION

PICA performed an inspection of a sewer force main using free-swimming leak detection, external electromagnetic scanning, and ultrasonic thickness testing, where appropriate, on approximately 5,900 feet of 8-inch PVC, 12-inch PVC, and 8 inch ductile iron pipe (DIP). The inspection findings were used by the City’s engineering consultant to determine the condition of the force main and identify recommended improvement projects and/or maintenance/monitoring programs.

Based on the findings of the visual observations, inspections, testing, and conversations with City Operations staff, the force main was observed to be in overall good physical condition. While some instances of corrosion/localized wall thinning were observed in the exposed ductile iron pipes that were tested, the observed conditions did not yet warrant full pipeline rehabilitation or replacement. The recommendations from the testing program were that observed conditions should be actively monitored, and tests should be repeated to document changes in pipe wall-thinning over time. Then, rehabilitation and/or replacement of the pipeline or pipe sections should be performed when conditions require such action.

News

Echoes of Innovation: Unveiling PICA’s Role in San Diego’s Water Pipeline Maintaining on KPBS TV

Delve into the high-tech realm where PICA is at the forefront of revolutionizing San Diego’s water pipeline maintenance. Our innovative approach, spotlighted in this captivating article, illuminates the path to sustainability and efficiency in urban water management. Experience the fusion of technology and expertise by reading the full article on KPBS.

Check back regularly for updates on where PICA will be in the coming months. We are committed to educating the industry on how PICA can help stakeholders obtain reliable and actionable pipeline data.

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

MEET THE TEAM

MEET THE TEAM

Why PICA?

Municipalities, asset managers, and pipeline owners and operators face a defining challenge in maintaining the integrity of aging infrastructure. The answer lies not in the monumental task of replacement, but in the strategic, intelligent approach championed by PICA. Embracing PICA’s service solutions is more than a business decision—it is an investment in the future, a commitment to safety, and a testament to responsible stewardship.

The critical infrastructure upon which society rests cannot be left to the attrition of time without intervention. Proactive inspections and condition analysis services are indispensable in the campaign to safeguard this infrastructure.

PICA’s commitment to “driving innovation in proactive inspections and condition analysis services” is not just a corporate purpose; it is an essential strategy for ensuring that our pipelines—these lifelines of modern existence—continue to serve us safely, reliably, and sustainably for generations to come.

Therefore, asset managers and pipeline owners and operators are not just choosing a service provider in PICA; they are partnering in a cause that upholds the safety and prosperity of our communities and environment.